DVP&R Design Verification Plan and Report

Table Of Content

Learn how Microsoft leverages Solido IP Validation to address IP quality issues early in the design process, saving time and money on potential (ECOs), improving overall IP quality in production and integration flows. The recommendation system is a disruptive machine-learning application that significantly reduces redundant efforts. Verification engineers receive recommendations of tests with the same intent as tests that were historically written. Selecting tests that efficiently verify a design or a change brings sophistication to verification process. Engineers can use this to optimize debugging by better understanding factors that contribute to errors in a particular design.

To join the conversation, and become an exclusive member of Electronic Design, create an account today!

Pick any image to create AI-powered designs by automatically removing backgrounds, enhancing colors, adjusting smart shadows, and so much more. The simulated local explanation in Figure 1 explains the impact and direction of impact of several input features on model outcome. SHAP clearly explains how combining all impacts from all features for a particular design leads to a prediction of no-error. Verification and validation are different processes with different goals that are often mixed up. Do not wait until the design is complete to conduct your design evaluation as this can lead to costly redesigns! Make sure to integrate it early in the process and iterate where possible leading up to the completion of your first design draft.

Design Verification & Validation Process

Design validation and verification are essential components of successful device development. With shared understanding among the team, as well as the right tools, you have solid framework for getting your device to market. With your new information in hand, from pre- or post-product launch, start reviewing. Go back through all your user needs, design inputs, and design outputs. Maybe testing during the verification and validation stages reveal issues that can only be fixed with a change to the design. Finally, don’t forget that design validation must include packaging and labeling, too.

Planning

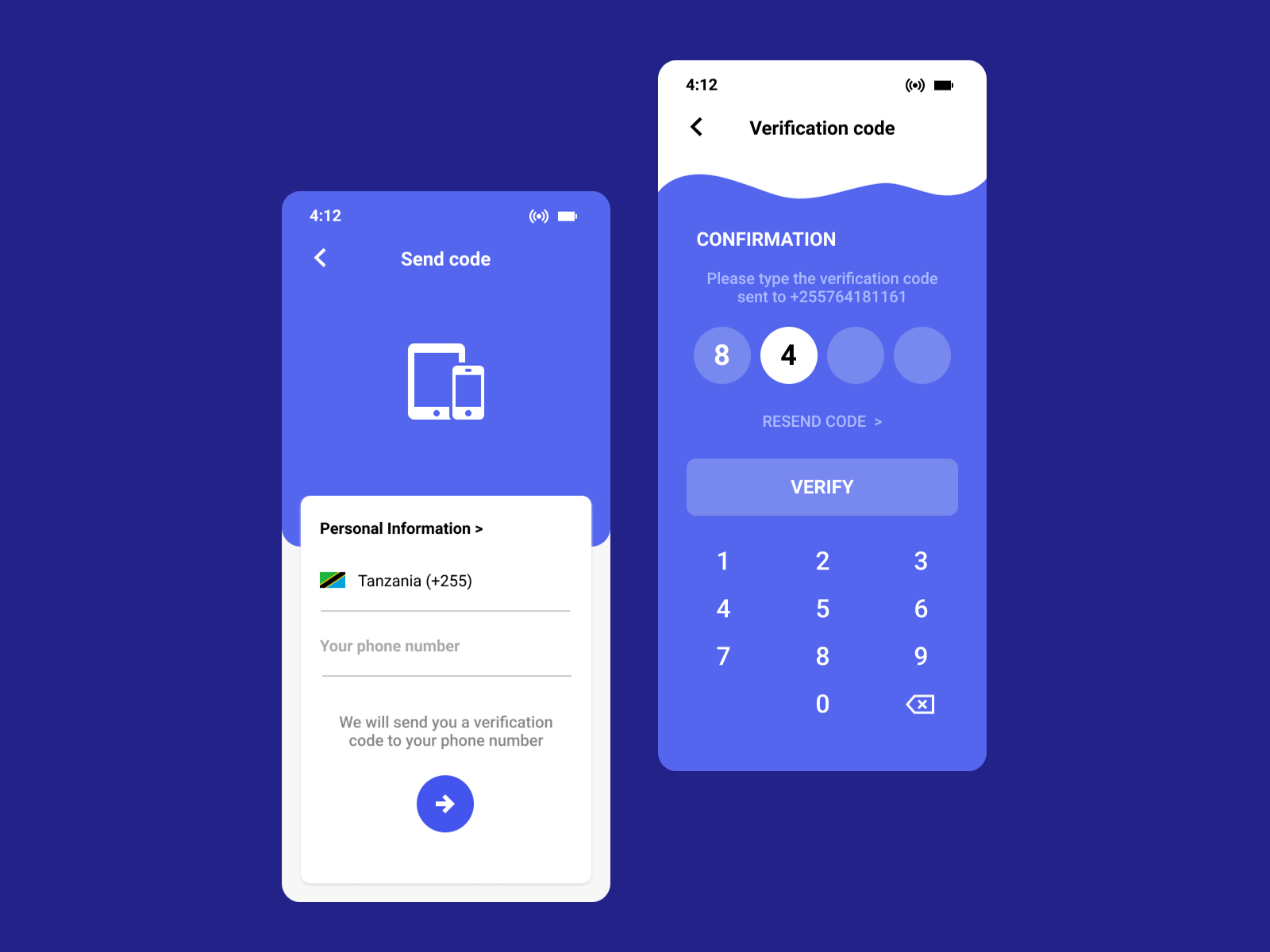

Depending on your chosen methodology you might need to create some usability testing scripts and scenarios. For instance, in our user testing example when testing the abandoned cart, we would need to create a detailed scenario asking the users to perform tasks within the checkout process. Before the app is launched, the design will need to be verified to make sure it meets the design specifications and that the outputs of the design are as expected. Skipping design validations can lead to a greater misalignment between the business’s strategic needs and the direction of the product. Without design validation, there is a great risk of the design failing to tick key business objectives which can harm the success of the product. Aligning users’ needs and expectations with the design is the best way to ensure that the product will be of service to its intended audience and a great predictor of the product’s success in the market.

Post deployment of the machine-learning model and its explanations using SHAP, verification engineers will receive suggestions/warnings of potential errors even before starting the debugging process. This makes debugging efficient and improves overall productivity and utilization of human resources planned for a project. For example, if your surgical instrument is supposed to be 12 inches long, you should produce an instrument that’s representative of your final product, measure it, and ensure it is the correct length. The same process applies to an instrument that is designed to meet a specific torque specification. To verify this, you would run a test on a statistically valid sample size that applies rotational force and ensure that it can handle that torque level. Greg Jung has more than 25 years of experience designing medical equipment and electro-mechanical products for a wide variety of industries.

Synopsys Lays Out The Benefits Of AI - Forbes

Synopsys Lays Out The Benefits Of AI.

Posted: Mon, 22 May 2023 07:00:00 GMT [source]

Beginner's Guide to Design Verification & Design Validation for Medical Devices

In some cases the new product is rushed to market without proper verification and validation. Consequently, product design or performance problems are not detected until after the product is already shipped. Too often, when new products are launched without adequate testing it results in field failures, product recalls, field campaigns, increased warranty costs and loss of brand equity.

Senior Validation Engineer jobs

This is one of the reasons design validation and verification are easy to mix up. Your design inputs—those physical and performance requirements—are derived from your user needs. Earlier I used the example of a user need for which a device must be capable of one-handed operation. With that distinction in mind, let’s take a closer look at both design verification and design validation, and how you can successfully execute both during product development.

Create logos, videos, banners, mockups with A.I. in 2 minutes

Experience the #1 QMS software for medical device companies first-hand. The output of this verification review is often recorded in a Statement of Compliance document. This document will list every requirement for the design, identify if the design is compliant or not, and list where this compliance is proven in the documentation. The purpose is to prove with objective evidence that the product satisfies the documents of user needs. The objective evidence is nothing but any physical proof of the output such as an image, text or audio file which indicates that the procedure has been accomplished. You need a typical user to test your product for an objective idea of its performance.

Why Implement Design Verification Plan and Report (DVP&R)

It gives your team flexibility to produce ad hoc views and reports to better use (and explore) the data you’ve captured. It provides V&V targeted data capture and reporting to make production of reports simple and repeatable. Since these tests should be run on production or production equivalent units, design validation tests are often the last tests performed.

In software testing, verification is static testing where designers test without executing any code. It looks at the performance of the product rather than its inner workings. Designify combines the world's most advanced visual AIs into one simple tool.

Although design verification and design validation have very different meanings, it’s easy for professionals to incorrectly interchange the use of the terms. Design validation is a comprehensive process of testing and validating a design to ensure that it meets the needs of the user while serving the strategic objectives of the business. Design validation is a quintessential part of the UX design process as it can massively help UX teams make informed improvements and create user-centered products. They’re steps in your design controls that are intimately connected to the rest of product development. And making sure those connections are clear and fully traceable is a fundamental requirement for any medical device company’s QMS. Design Verification is a method to confirm if the output of a designed software product meets the input specifications by examining and providing evidence.

We have been extensively discussing about different topics that are related to design verification and validation, such as biocompatibility, sterilization, reprocessing of single use device, clinical evaluation. Resources that you might need for your design validation include analytic tools or even peers. Recruiting participants can also be tricky so factor that in when allocating money and time to your design validation project. Without conducting a design validation you will never know if your design aligns with the user needs and the business goals. If you decide to skip the design validation stage and jump straight to development you are at high risk of developing a product that will fail to serve your users. Validation – Establishing by objective evidence that device specifications conform with user needs and intended use(s).

PrimisAI Forms to Revolutionize Hardware Design with Leading AI Solutions - Design and Reuse

PrimisAI Forms to Revolutionize Hardware Design with Leading AI Solutions.

Posted: Wed, 27 Sep 2023 07:00:00 GMT [source]

Learn how NVIDIA leveraged Solido Additive Learning technology to speedup standard cell library verification with Solido Design Environment while maintaining the same accuracy on verifying a new PDK revision. Adjust smart shadows, or automatically match the colors of your design elements. The recommendation system is a system that filters data to recommend the most relevant action.

Unit tests, on the other hand, focus on testing individual units or modules of the software to verify their functionality and performance in isolation. This helps identify any flaws or defects within the individual units before they are integrated into the larger system. Finally, system verification tests validate the overall functionality, performance, and interoperability of the entire system, ensuring that it meets the defined requirements and specifications. It is worth noting that design verification and validation are iterative processes that should be performed in conjunction with other design control activities. Manufacturers should document and maintain a comprehensive Design History File (DHF) that includes evidence of both verification and validation activities, along with other design control records.

Comments

Post a Comment